Dapol B800 Motorised Track Cleaning Wagon Reviewed

The Dapol motorised track Cleaning Wagon – reviewed. The model, serial number B800 in purple livery, has been around for a number of years, priced at an average of £80 or just under. The vehicle I’ll be reviewing has been on my layout for a number of working years, and has seen considerable wear, doing what it was designed for (and considerably more).

The above photo shows the Dapol track cleaning wagon on my layout.

First Impressions

I don’t think it’s meant to look like or resemble anything that is or was ever in use on the British Rail network. Although it’s comparable to the Railvac. Aesthetically it looks good. The vented cover at the top can be removed to clear out dust and there is a button on the top for on/off control.

The larger of the black circles is a manhole in which cleaning fluid can be inserted. The model is fitted with NEM pocket couplers, which hang down towards the sleepers so the hook may catch on points.

Wagon Operation

I’ve never really run this model as part of a consist, because the cleaning pads on the bottom cause a lot of friction and catch on junctions and crossovers causing it to derail itself and other wagons. The wagon, when switched on, draws its power from the rails like any other locomotive or rolling stock.

The wheels are mostly metal and where the wheel inserts into the bogie frame, this bogie frame is partially metal. The metal clipping on the inside of the wheel frame leads up to two screw like structures which, as well as aid balancing and rotation of the bogie and vehicle on the track, also conduct power to the vehicle through means of contact with a metal plate onboard, seated just above the bogie. As such, the bogies aren’t connected to the wagon via wires.

As seen in the photograph above with the vents removed, the two wires from the rightmost wheelset, run along the inside of the vehicle. The part holding the DAPOL logo in the picture above, said casing can be removed. Removal of the body casing is achieved by means of removing the bogies and using a screwdriver. Upon removal of the body casing, the motor – a similar type to those used in the Devious Diesel class 10 shunter, and the BR pug (a vertically mounted small motor, smaller than that of the cheap 0-4-0 locomotives). This motor propels a cylindrical fan which draws dust (and any loose ballast or sand you may have laid) into the vented chamber beside it.

Wagon Review

The wagon itself does not perform well when towed by a locomotive as the couplings are low and can catch on pointwork or diamonds, as well as the abrasive cleaning fur / pad on the bottom. I haven’t tested the use of cleaning fluids.

The wagon vacuum is powerful enough to “hoover” up ballast, sand or any other lightweight debris on the track. Very useful for me, as I tend to use sand and Gaugemaster ballast in my Dapol IOA and JNA wagons, and these do periodically detail spilling the load all over.

When running the Dapol track vacuum, I personally turn the track circuit power on maximum and push the cleaning wagon to the worksite by hand. When vacuuming up spilt ballast or sand, I recommend covering the vents with a tissue so that it drapes down and touches the baseboard. This is because when vacuuming, the wagon can spit out stray bits of ballast or dirt, all over the place. Not very nice if you get it in your eye.

Also worth noting if clearing up a spilt load, the cylindrical turbofan has a tendency to get jammed. Gently rotating the fan with your finger whilst the power is on full should help get it running again (although probably best not to stick your fingers in any moving parts…maybe ignore that bit.).

I’m guessing really that the cleaning wagon was made not for hoovering up spilt wagon loads in large quantities, but for more general purpose maintenance of running it round a few times on a Friday night. Therefore it’s no wonder that my motor got completely seized.

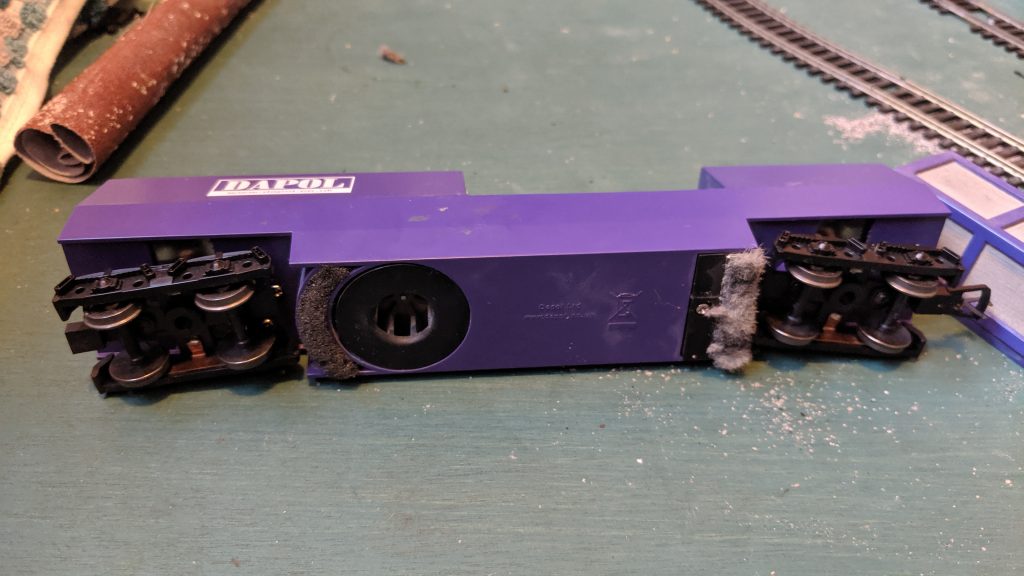

The above photo shows the bogies, along with the cylindrical fan and the cleaning pad, which is fixed on to the bottom. I haven’t attempted to replace or remove it, because I use other things for rail head treatment trains.

In terms of effectiveness at cleaning the rail heads, I cannot comment on this as I have never successfully run the unit in consist without it causing problems. I also tend to loosely ballast my sleepers, so have no use for it other than clearing up spilt wagon loads. For railhead cleaning, I use the affordable axle hung cleaning pads by Gaugemaster. These clip on to the wheel axles on most coaches and bogie wagons and are somewhat effective at clearing loose dirt.

In Summary

The track cleaning wagon isn’t really worth the £70+ pricetag. It’s really only useful for light dirt or dust on the track, which you could remove with the aforementioned Gaugemaster axle hung cleaning pads. The vacuum fan gets jammed by large amounts of OO gauge ballast or sand so really a £14.99 Henry Desk Hoover from Argos would probably be the way to go.

POSITIVES: it’s useful for lightweight sucking. It can be pulled around the track by a shunter or something but may derail or be too heavy due to friction from the cleaning pads.

NEGATIVES: £70 isn’t cheap, although most wagons aren’t these days. Wagon frequently details on pointwork due to the low underframe and cleaning pad. Vacuum isn’t really effective. Gets jammed easily.

I have seen this unit operating on other layouts, and it seems to be reasonably effective, though the coupling problem is fixable with thin plastic shims. I agree that it is pricy, and RMweb has an article converting a Lima BRmk1 coach to a vacuum cleaning coach utilizing a computer keyboard cleaner, which seems to me to be a cheaper alternative.The use of masonite skids under a bogie coach or wagon, first used on the Gorrre&Daphetid RR in the US in the 1950s, and which is part of a regular train, is probably sufficient for most track cleaning purposes, and are a the quite good supplement to your clip on axle pads,